This project is being conducted in collaboration with the Advanced Research Laboratory for Multifunctional Lightweight Structures (ARL-MLS) at the University of Toronto, supervised by Prof. Kamran Behdinan.

(link to the lab: https://arlmls.mie.utoronto.ca/)

(download the complete design report here)

This project ranked FIRST out of more than 80 entries in the 2024-2025 University of Toronto Mechanical Engineering Capstone Showcase, AWARDED $1000.

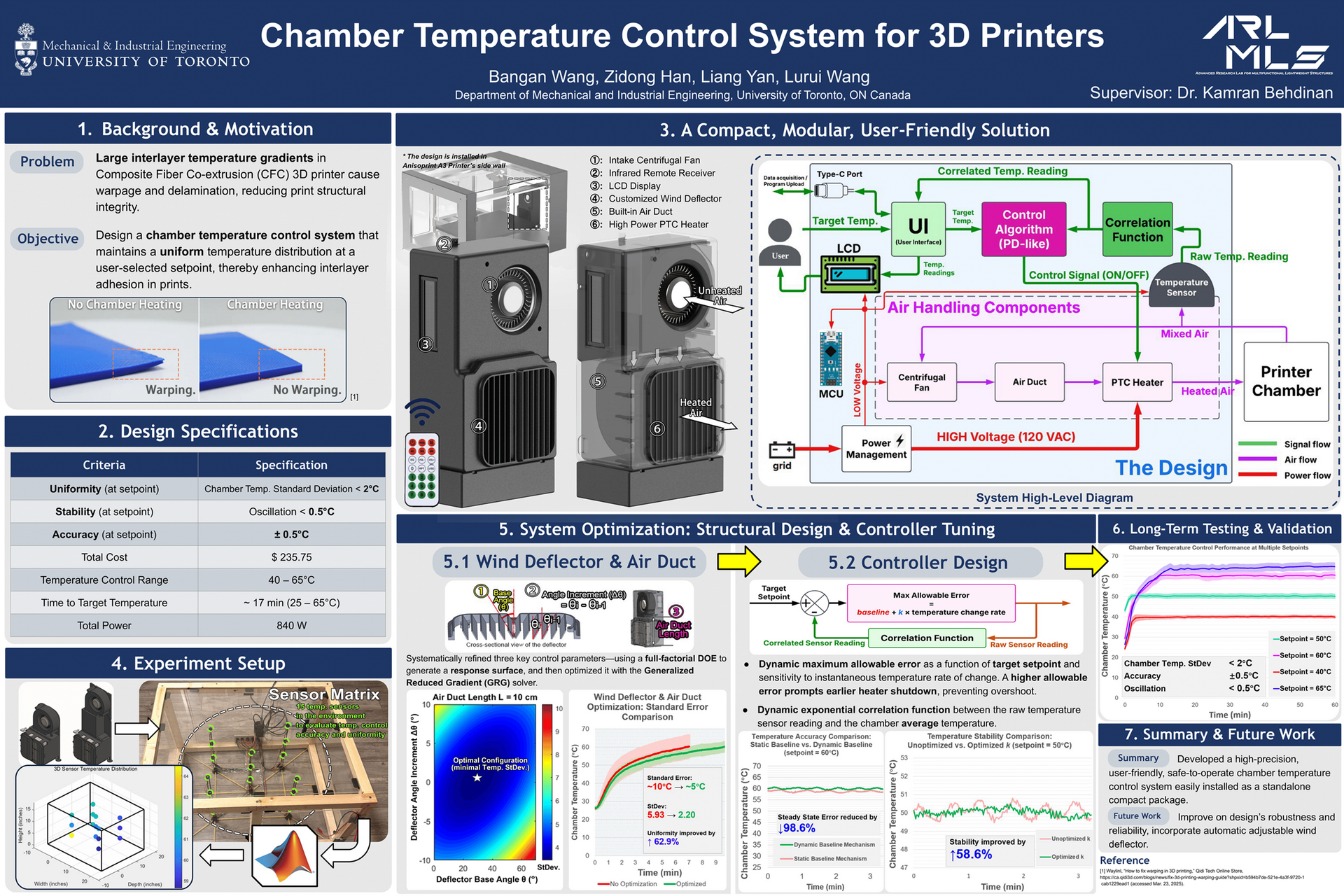

Aims to design a temperature control unit for the Anisoprint A3 CFC (Continuous Fiber Co-extrusion) 3D printer, to mitigate the problem of non-uniform cooling between adjacent printed layer that cause edge warpage and delamination.

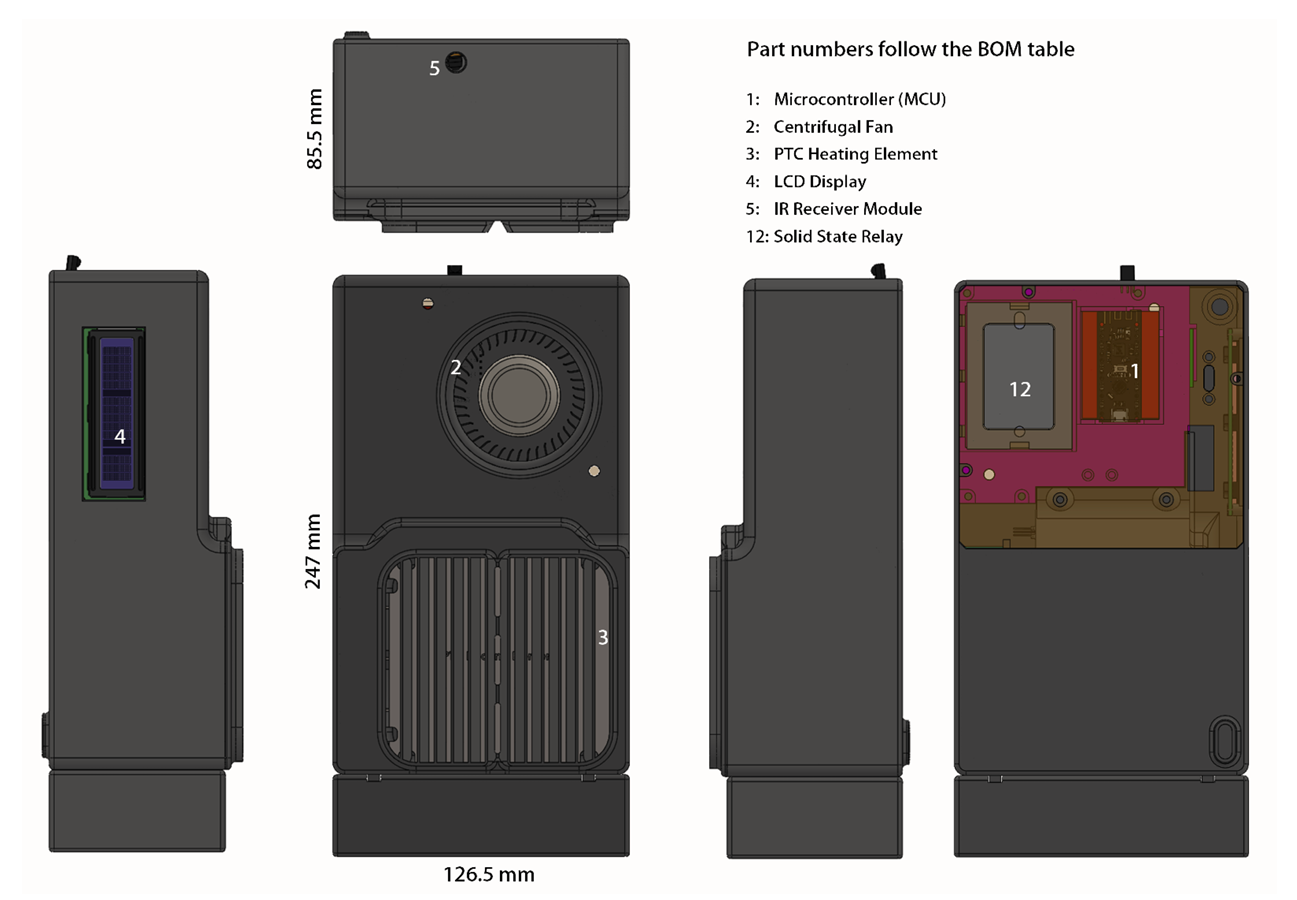

A single-packaged, user-friendly control unit has been designed and prototyped.

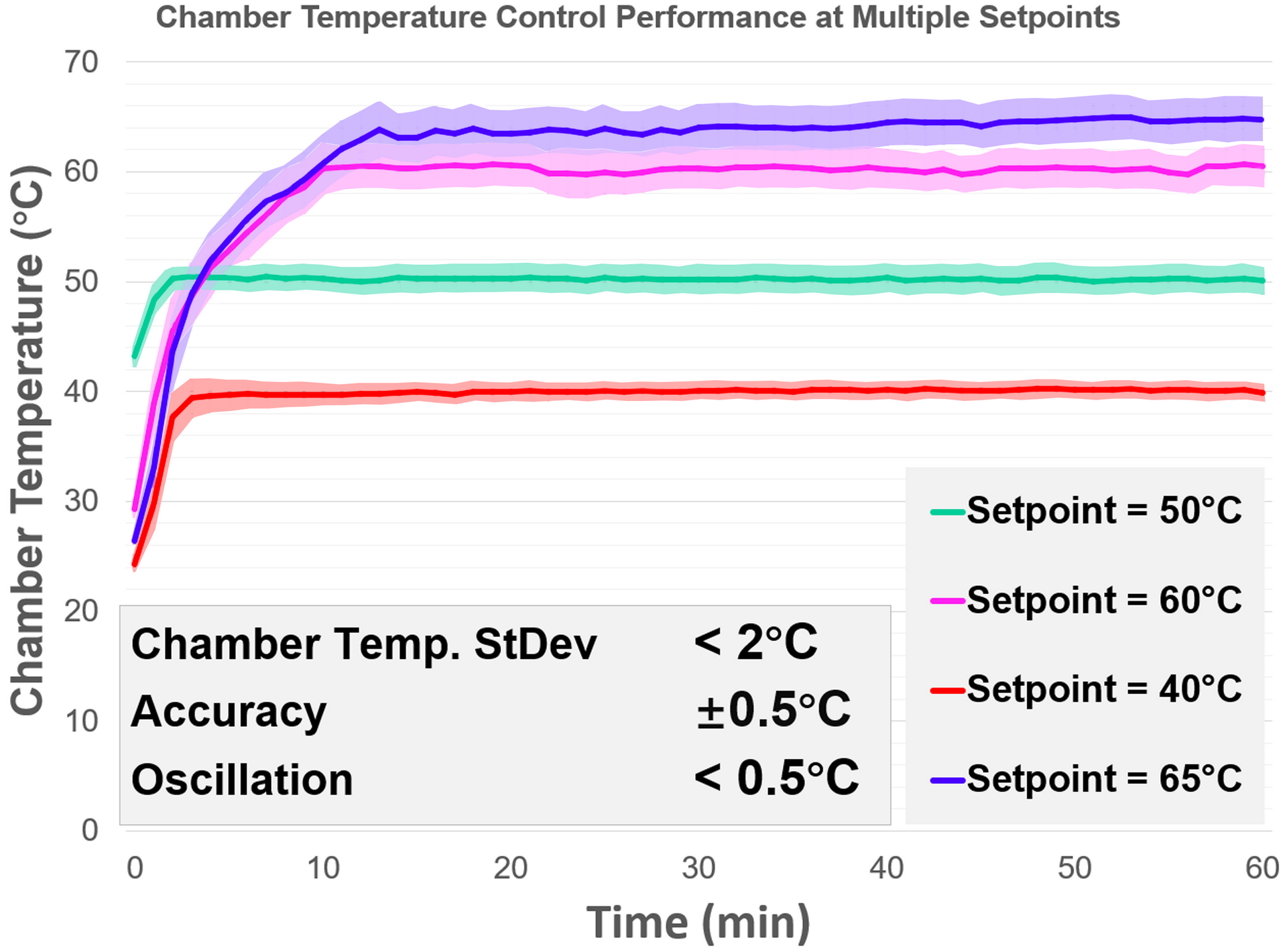

The design is capable of heating a nearly half-cubic-meter printer chamber from room temperature to any target between 40°C and 65°C, with error within ±0.5°C, oscillations under 0.5°C, and a temperature uniformity of ±2°C across the entire chamber.

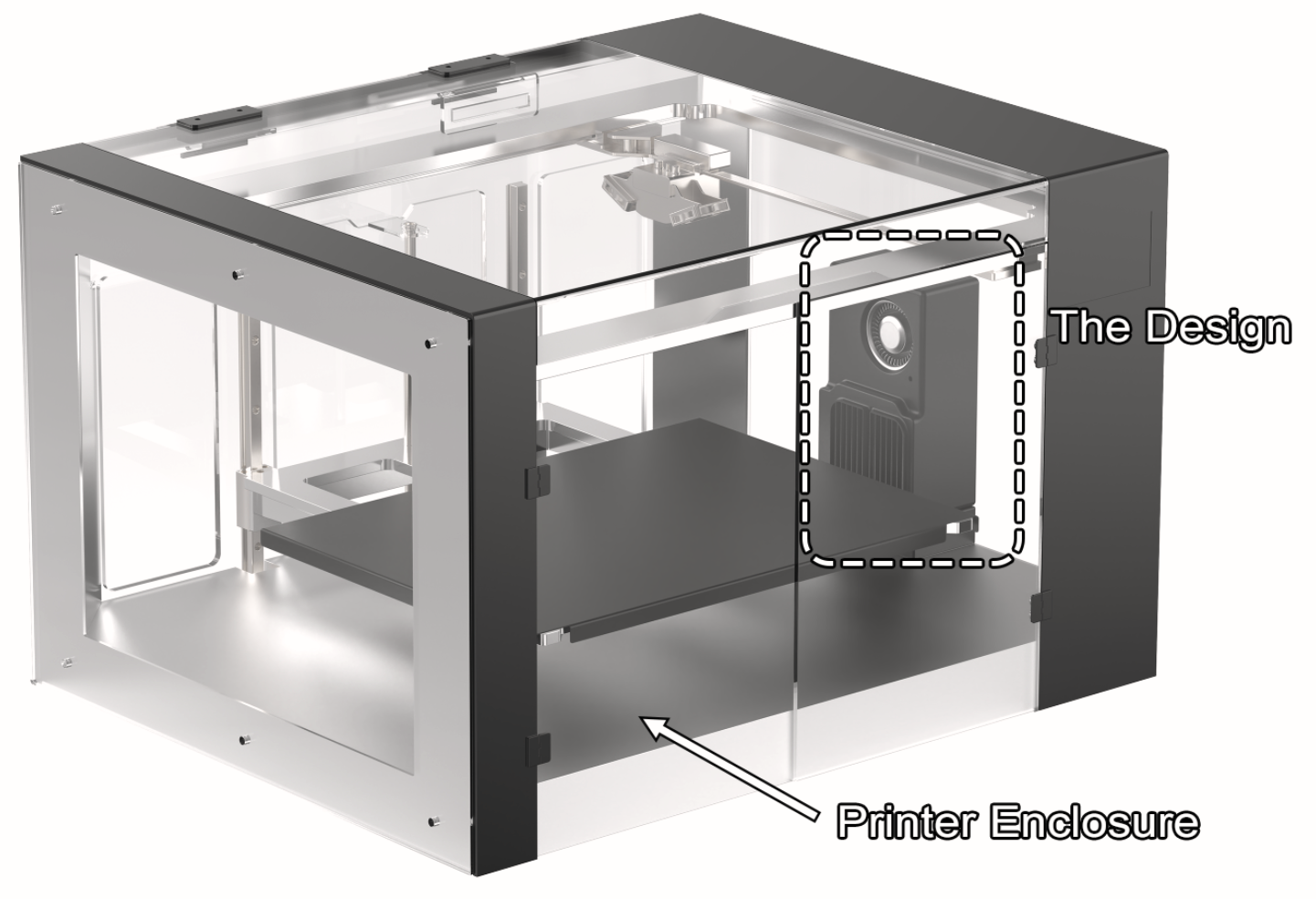

The Design in the Printer

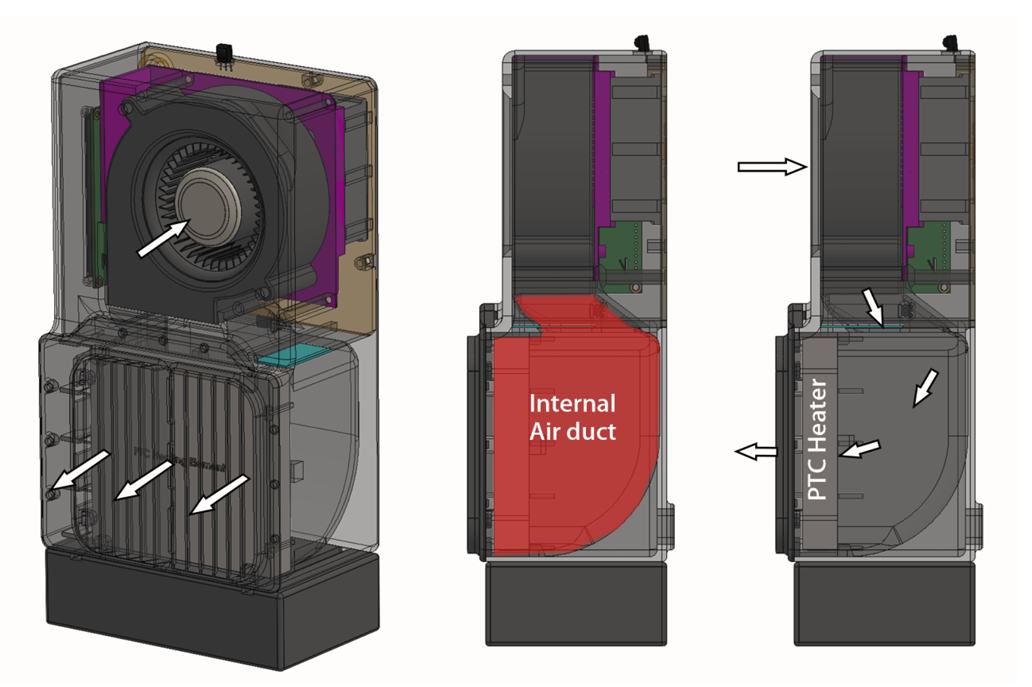

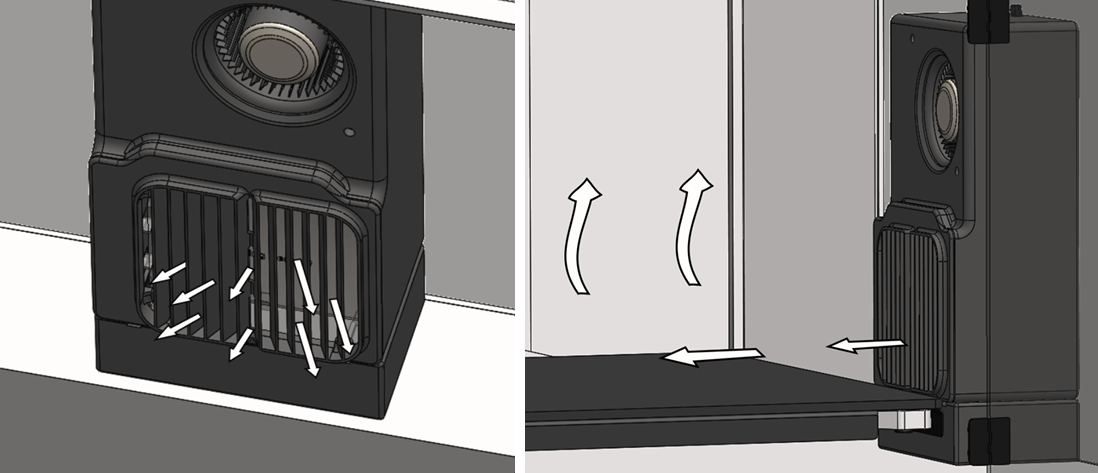

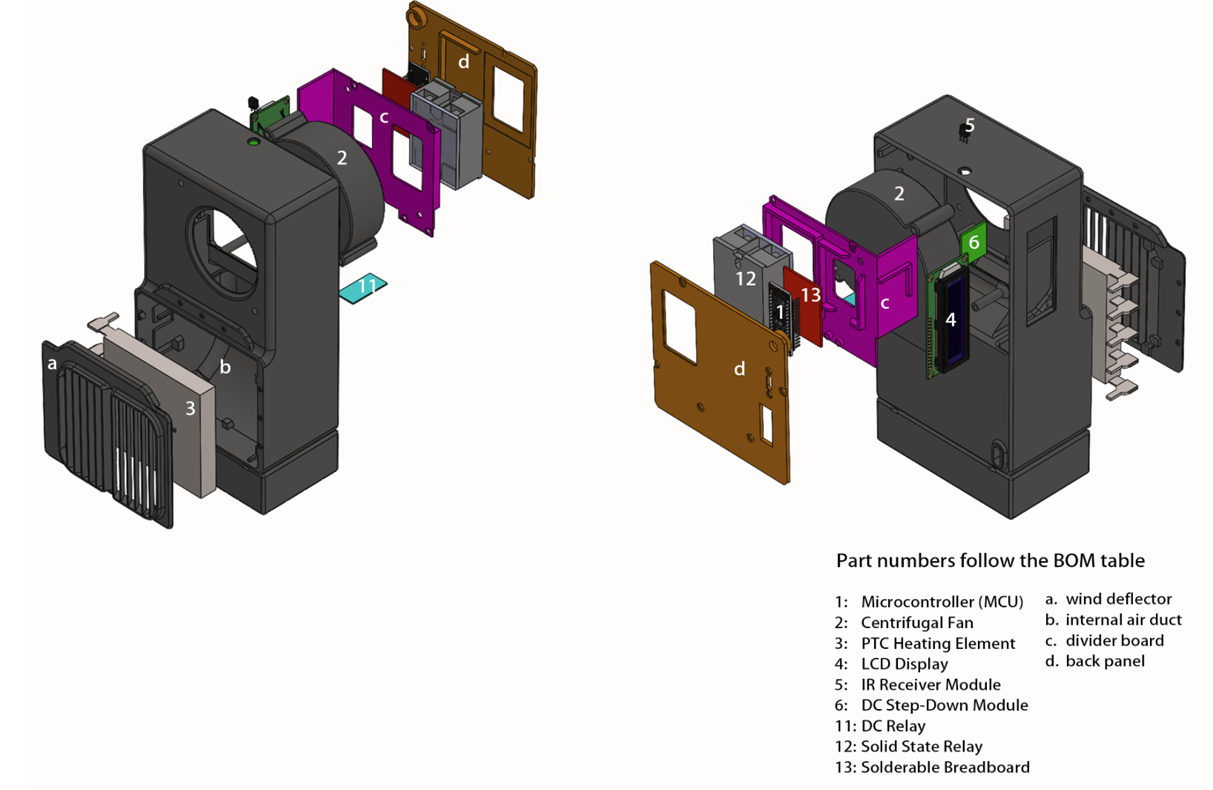

The system uses forced convection to heat the chamber.

Unheated air is drawn in by a centrifugal fan at the top, forced through an enclosed air duct across a high‑power PTC heater at the bottom, and then introduced into the printer enclosure via a specially designed deflector at the outlet.

Users can adjust the target temperature by a remote. Both the current and set temperatures are displayed on the LCD screen.

The design uses a special-designed correlation sensor and a PD controller to regulate the temperature.

Airflow Direction

Air Spreading Direction

Explosive Diagram of the Design

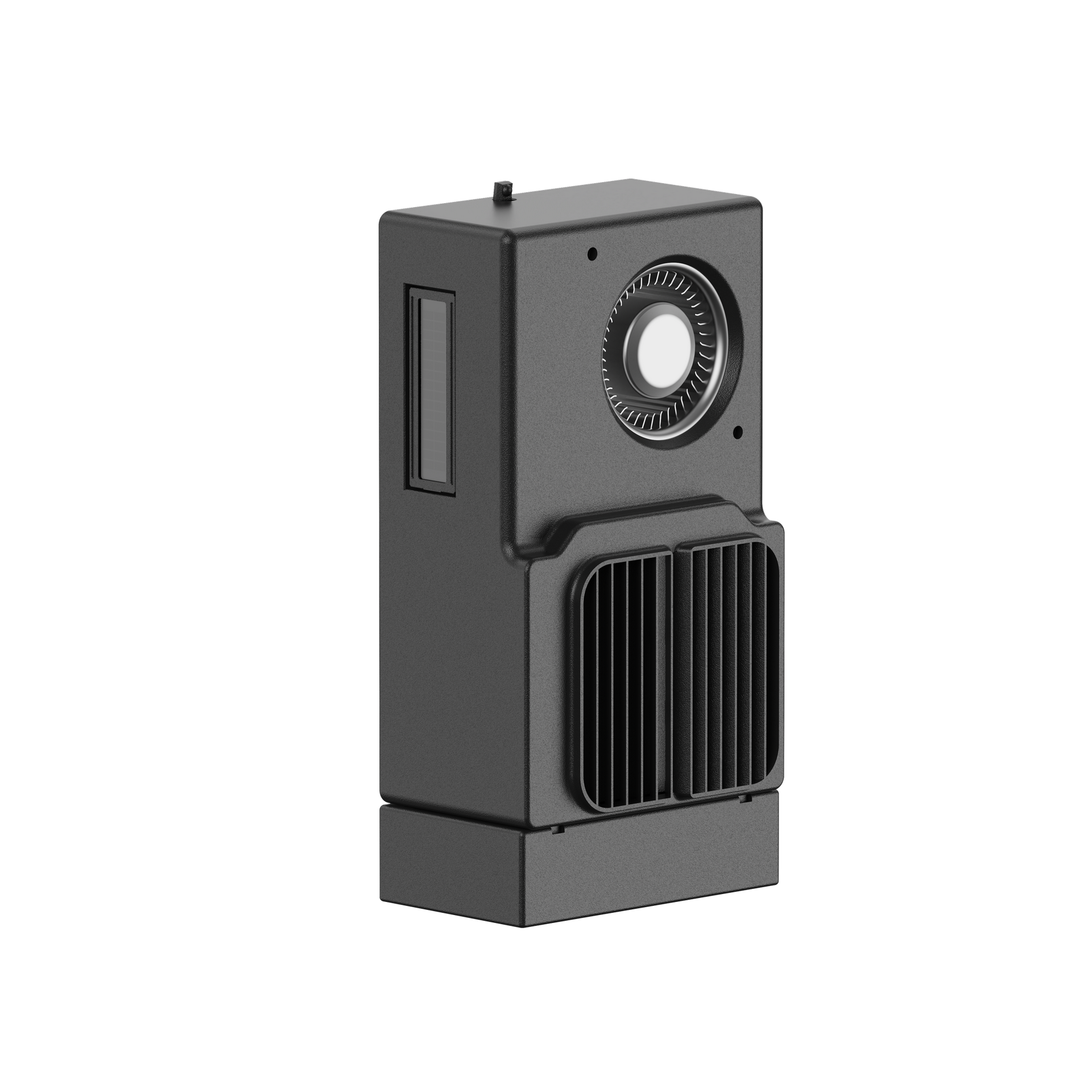

Product isometric diagram

Product isometric diagram (transparent)

The design delivers a high-accuracy, high-uniformity, and high-stability control outcome.

*StDev stands for standard deviation of temperature throughout the chamber

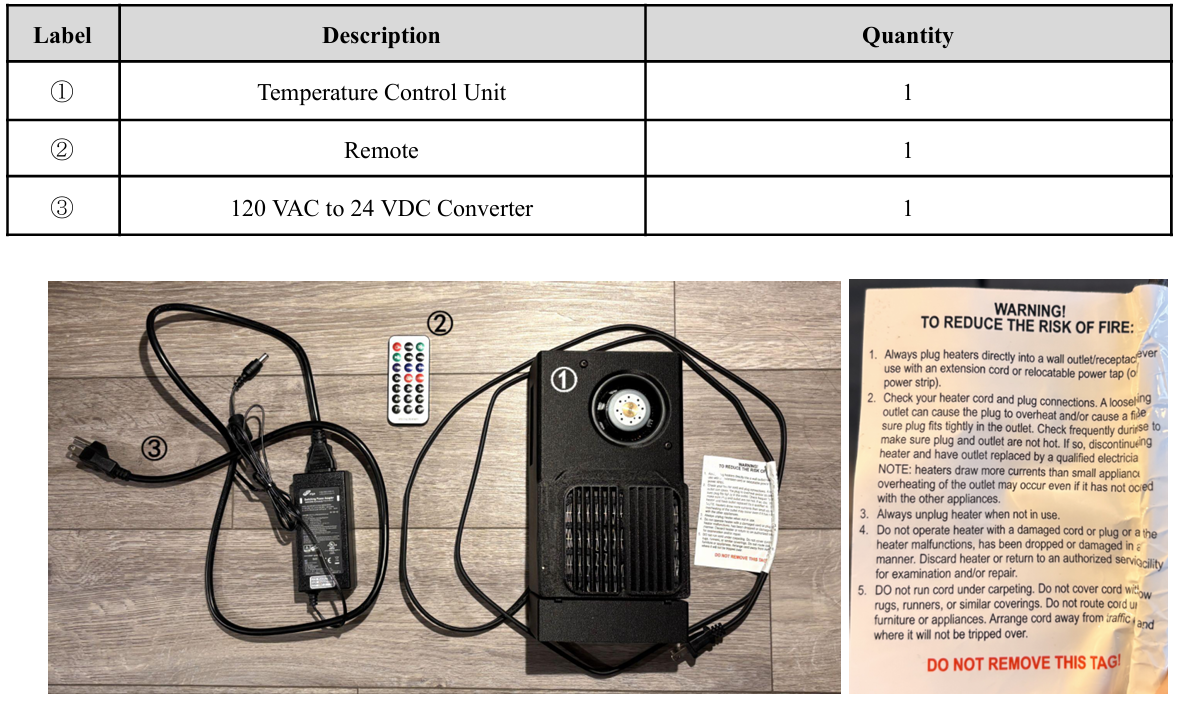

Product Package

Prototype Product Photo (left: front; right: back)

As the team leader, I was responsible for:

Mechanical & Electrical Design & Prototyping

• Produced the complete CAD model, including internal compartments, mounting holes, and airflow ducts.

• Designed the schematic, laid out the PCB, and carried out board soldering.

• Prototyped and assemble the design.

Air‑Flow Optimization

• Ran a full‑factorial Design of Experiments (DOE) to optimize the deflector geometry and duct length.

• Improved in‑chamber temperature uniformity by 62.9%, achieved in-chamber uniformity of 2°C.

Adaptive PD Temperature Control

• Developed a PD controller whose proportional gain adapts to the target set‑point. Fine tune the terms using a method of enumeration. Cut steady‑state error by 98.6 % and boosted temperature‑control stability by 58.6 %.

Chamber‑Wide Temperature Calibration

• Created a self-adaptive correction model that maps the single sensor reading to the entire chamber’s spatial average temperature. Ensures the controller acts on a reference that can accurately represent the entire space.